How Ruana Knives are Made

Introduction

Anyone who has tried to make a knife on their own is aware that it isn’t easy work. For 80 years, a little blood, a lot of sweat and an occasional tear have gone into making Ruana Knives. Hot, loud, dirty, physically demanding, monotonous, and dangerous are a few of the words to describe the work that takes place at the Ruana Knife Works shop. Each knife is manufactured using power tools, hand tools, and machinery that requires hands on work throughout the production process. All knives are crafted one at a time with attention to detail given at every step along the way while keeping quality our number one priority from start to finish.

The Blade

Rudy Ruana was once quoted as saying, “you pay for the blade and the rest is free.” While not totally true, the main goal at Ruana Knife Works, Inc. has been and will always remain to produce a cutting tool that will be reliable for its owner. Each Ruana blade is made from high carbon steel that is hammer forged, hollow ground, individually oil quenched, and heat treated using a zone tempering method that makes the spine of the blade a little softer than the cutting edge. Our high carbon blades are not stainless, but they contain the best steel for a knife that provides a great cutting edge, will stay sharp, and is relatively easy to sharpen. With minimal care, they will last you a lifetime and then some.

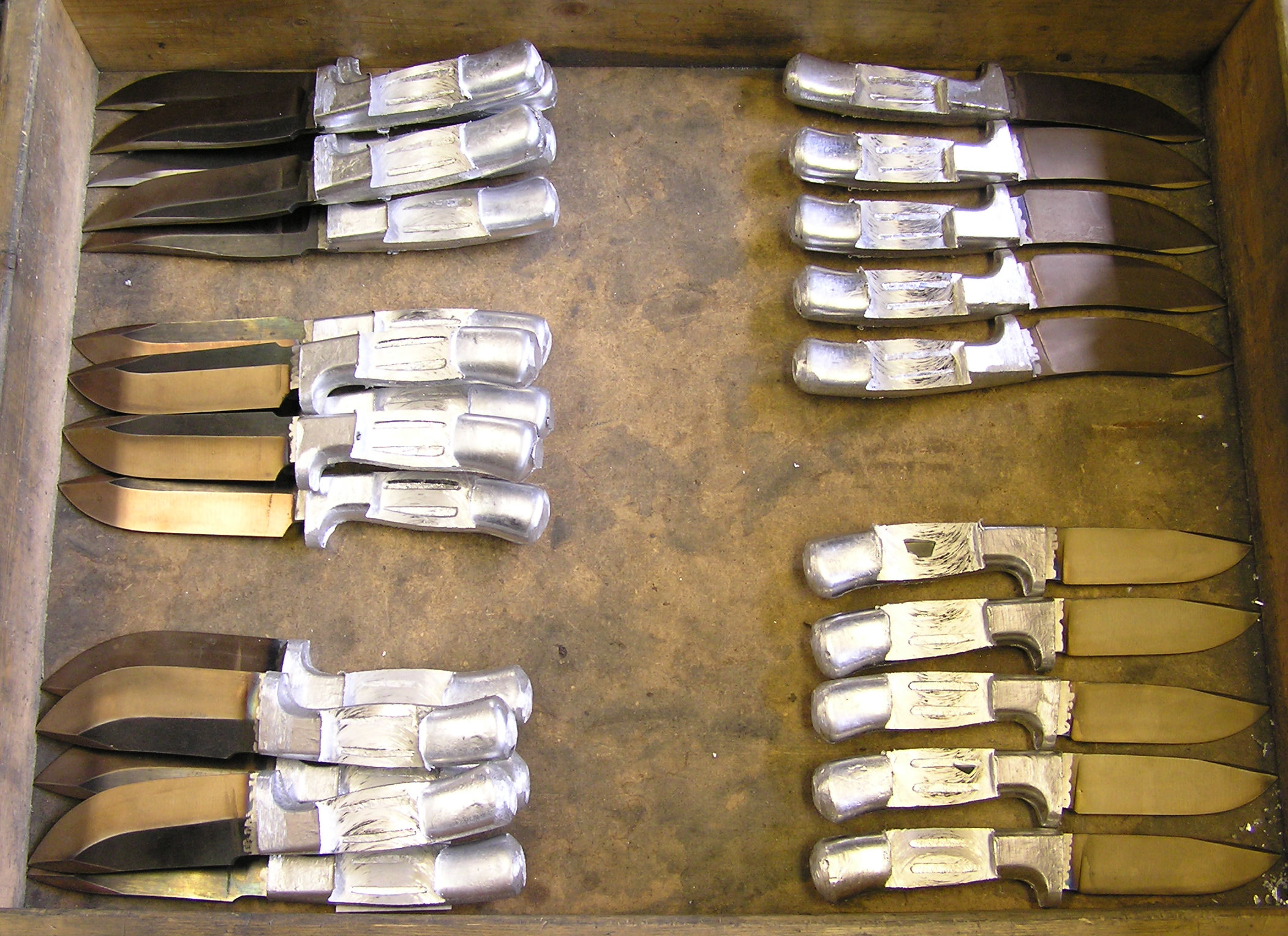

The Handle

Ruana Knife handles come in several different forms. The most common knife handle is aluminum cast directly on the tang with elk antler inserts that are beveled and riveted. The tang runs inside the entire length of the handle and cast aluminum produces a strong handle that will not fall apart – it is there to stay unless you take a cutoff saw to it. We also make custom handles that have full tangs with slabs from elk antler, micarta, or wood that are epoxy glued and contain rivets to strengthen the handles. Our brass-handled knives are the prettiest, but are also made to be used. The tang runs through the entire length of the handle and the butt cap is threaded onto the tang with some butt caps being recessed. Epoxy glue is used to strengthen and secure these handles, which are most commonly made with elk antler although other materials are used occasionally.